Our Capabilities

Low Volume Production • Prototyping • One-Off Machining

CNC Milling

Our Haas VF1 has made almost all our products and the vast majority of one-off parts that you see on our social media and website. Since getting our mill in 2017 it has made thousands of parts and run for over 3000 hours. Our VF1 has a machining work envelope of 20"x16".

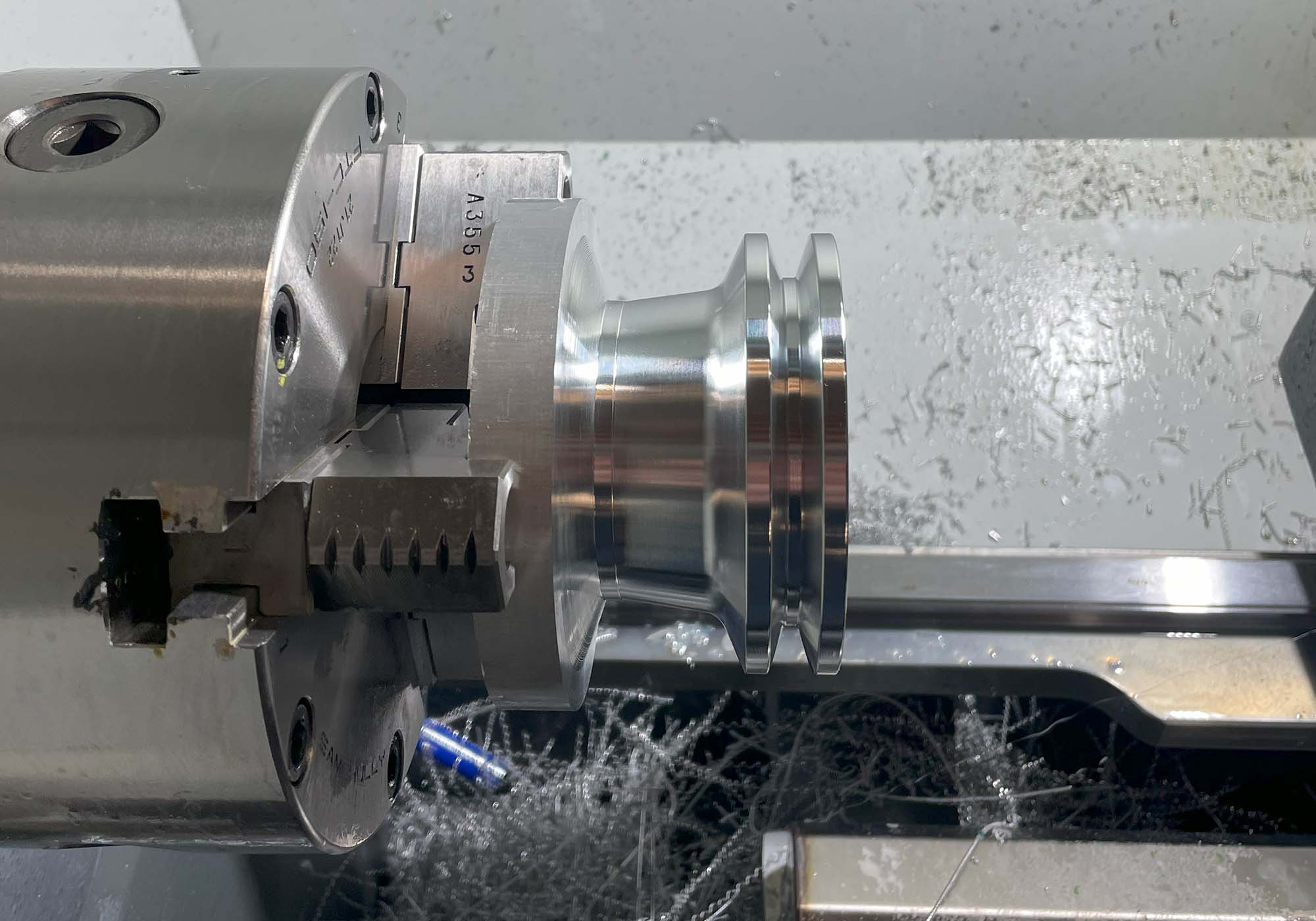

CNC turning

Our Haas TL1 is a small, but mighty CNC lathe setup to machine one-offs and prototypes. Since getting it in 2022 we have used it to make many one-offs and prototypes on future products.

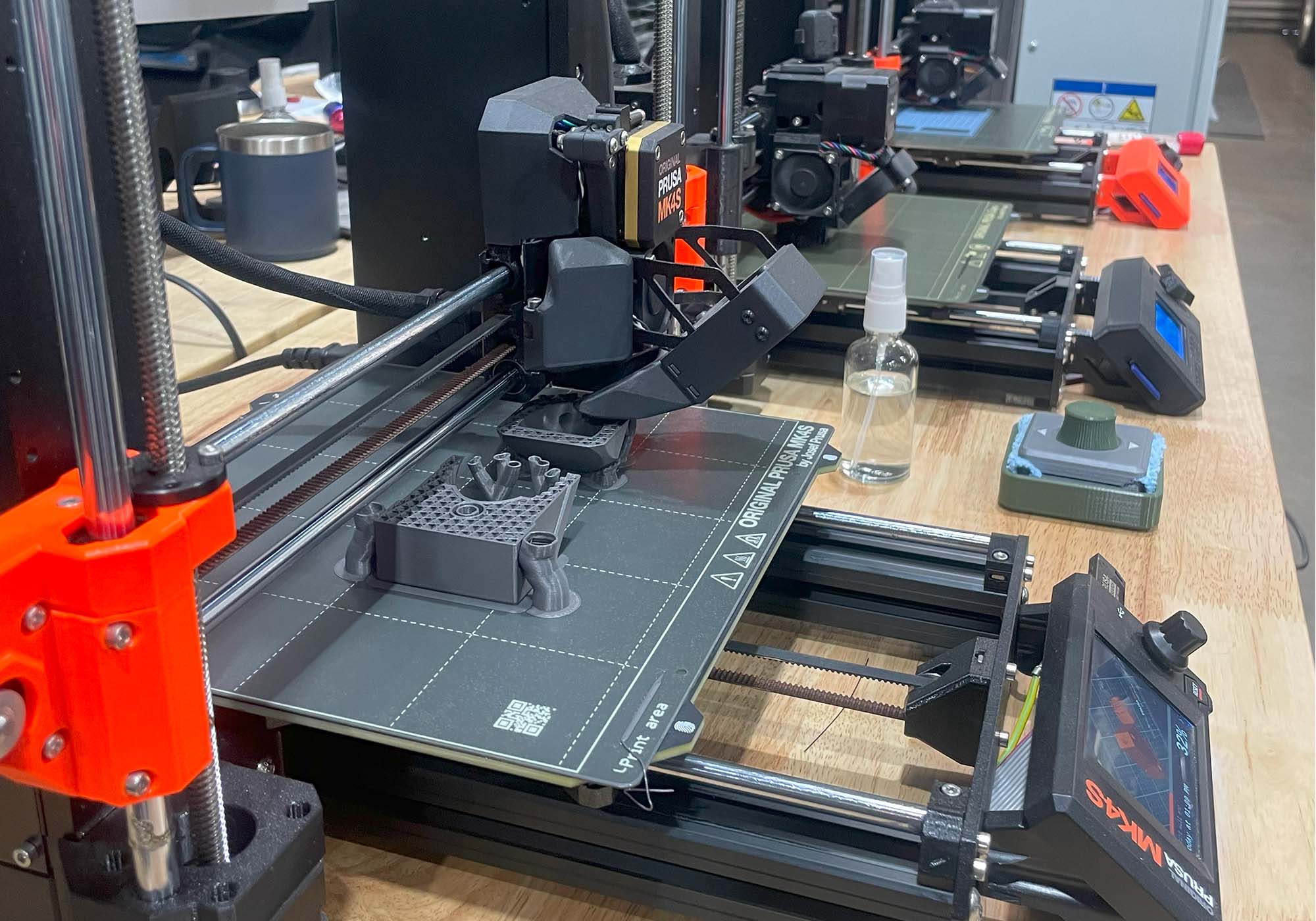

Prototyping Using 3D Printing

Since 2021 we have built up two Prusa mk3's and one Mk4 (our own mini print farm). Only having a build volume of 9.84" x 8.3" x 8.6" they may be small, but they allow us to rapidly iterate our designs always making things better.

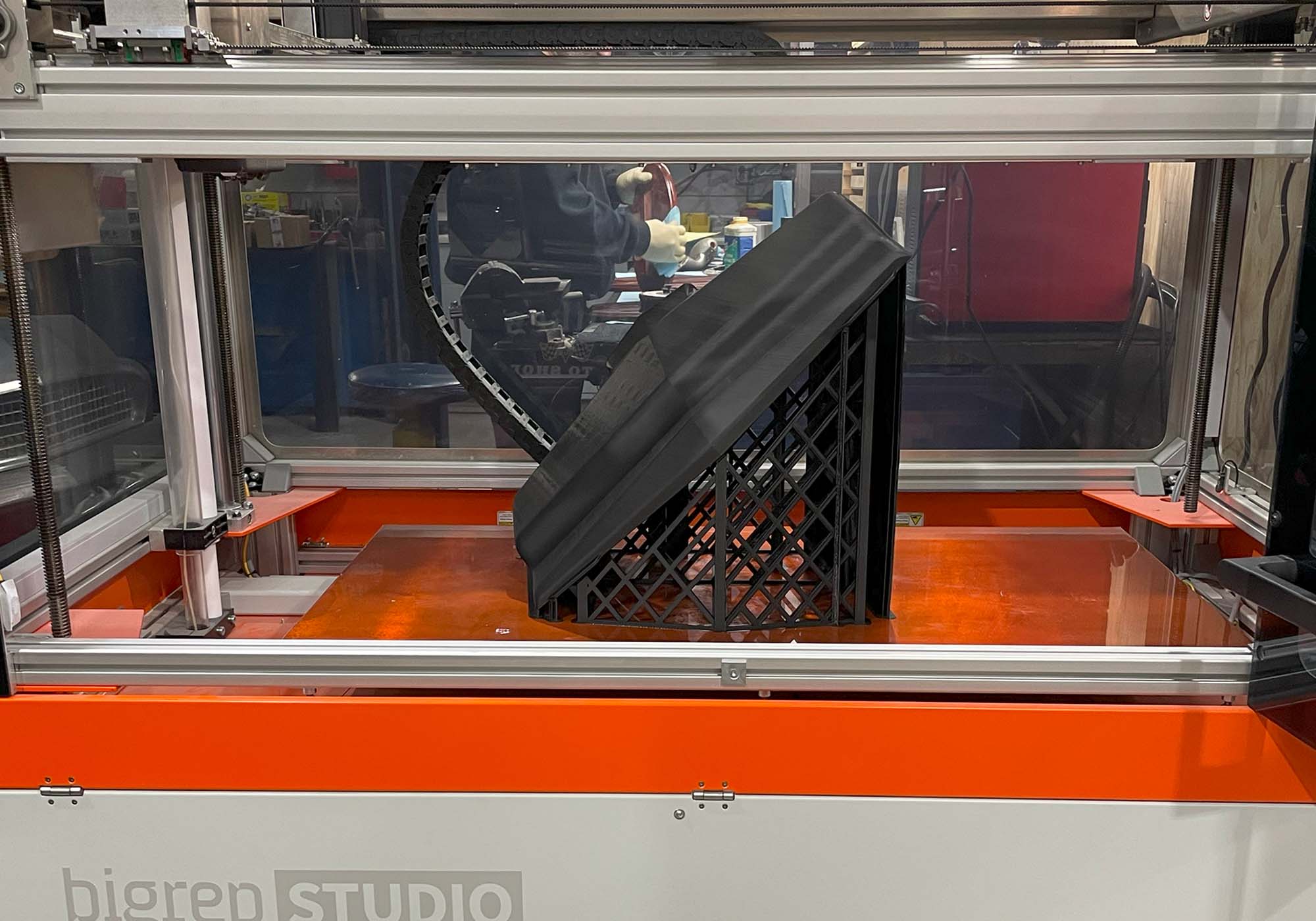

Large Format 3D Printing

Last year we got ourselves into large format printing with our Bigrep Studio. With a build volume of 40" x 20" x 20" this allows us to make large prototypes and we have even started making interior pieces with it. One cool example was creating a custom steering wheel outer ring for a 1932 GMC that Roseville Rod & Custom built.